鋼管生產過程介紹全書(英文版)【下載】

Steel Tube and Pipe Manufacturing Processes

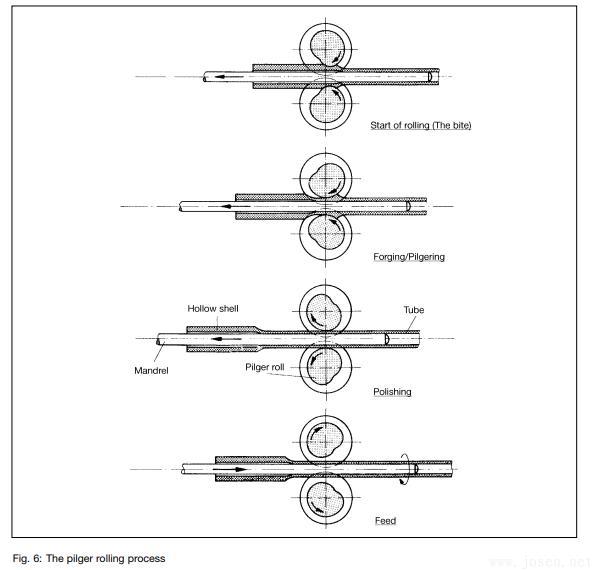

The advent of rolling mill technology and its development during the first half of the nineteenth century also heralded in the industrial manufacture of tube and pipe. Initially, rolled strips of sheet were formed into a circular cross section by funnel arrangements or rolls, and then butt or lap welded in the same heat (forge welding process). Toward the end of the century, various processes became available for the manufacture of seamless tube and pipe, with production volumes rapidly increasing over a relatively short period. In spite of the application of other welding processes, the ongoing development and further improvement of the seamless techniques led to welded tube being almost completely pushed out of the market, with the result that seamless tube and pipe dominated until the Second World War. During the subsequent period, the results of research into welding technology led to an upturn in the fortunes of the welded tube, with burgeoning development work ensuing and wide propagation of numerous tube welding processes. Currently, around two thirds of steel tube production in the world are accounted for by welding processes. Of this figure, however, about one quarter takes the form of so-called large-diameter line pipe in size ranges outside those which are economically viable in seamless tube and pipe manufacturing.

Chart I provides an overview of the size ranges for seamless (DIN 2448) and welded (DIN 2458) tube. As is evident, welded tube is predominantly manufactured in ranges characterized by small wall thicknesses and large outside diameters, while seamless tube is produced mainly in the range extending from normal to very large wall thicknesses in the diameter range up to approx. 660 mm. The process of selection of the manufacturing process – especially in the overlap regions where there is a real choice between seamless and welded tube – is essentially dictated by the application of the tube, i.e. the associated material requirements and the service conditions.

Chart II provides a summary of the main manufacturing processes applied nowadays in the production of seamless and welded steel tube. Also indicated are the upstream production stages, any downstream further processing operations, and the typical products of the individual technologies. This scheme has been applied in order to illustrate the fact that a varying number of production stages in the starting material preparation or roughing stage are required to serve the various facilities of the tube production stage.

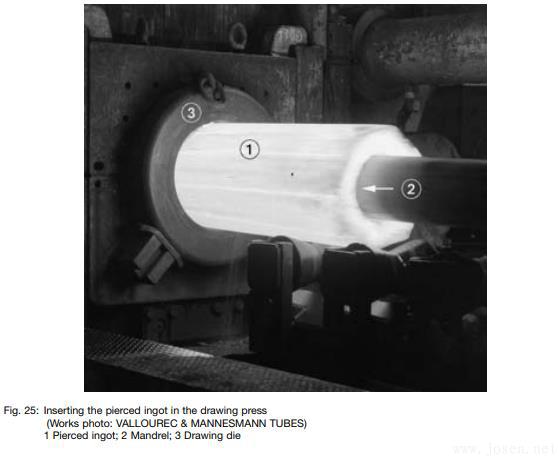

In the case of seamless tube and also in the case of the Fretz-Moon welding process, the production stage invariably involves a heating operation, in which case the product may also be referred to as hotformed tube or pipe. Downstream facilities for hot drawing or hot expanding occur relatively rarely; on the other hand, hot-formed tubes are extensively used as starting products for a downstream cold forming process. The latter is used in order to extend the product mix of a plant toward smaller diameters and wall thicknesses (DIN 2391), to reduce wall thickness and diameter tolerances, and to achieve special surface finishes or mechanical/thermo-mechanical properties in the tube.

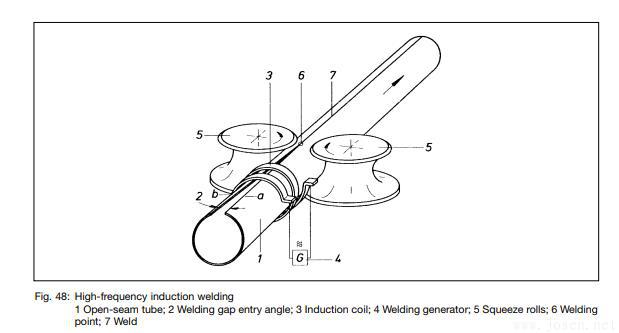

The production of welded tube initially involves the continuous forming of strip, sheet or plate in roll stands (sometimes referred to as roller cages), or in presses (U-ing and O-ing; C-ing process). The strip may also be cold-formed on a three-roll bending machine and subsequently welded by pressure or fusion welding to produce the finished tube. Depending on the forming process, a distinction is made between longitudinally welded and spiral-welded tube; the latter may also be referred to as helical seam pipe.-

As the requirements imposed on tubular products continued to increase, not only were the associated manufacturing processes constantly improved, but also appropriate systems for effective production control and quality assurance were introduced. Nowadays, tube and pipe manufacturers of renown all have a system in place enabling the production process from the steelworks to the finished tube to be continuously monitored and documented for total traceability, and effectively controlled on the basis of quality criteria. The mechanical and nondestructive tests stipulated in the relevant technical specifications are carried out by personnel operating independently from the production control department so as to guarantee product of a constantly high quality.

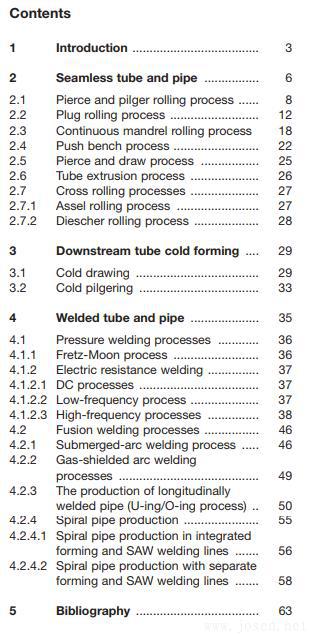

目錄:

這本書主要供給做鋼管外貿的朋友們,是用來和老外吹牛的百科全書。

全書下載網址:鋼管生產過程介紹全書(英文版)【下載】

| |